Clarion Hotel Lexington, KY: 265-Room LiDAR Scan & Full Revit Model Delivery

Project Description

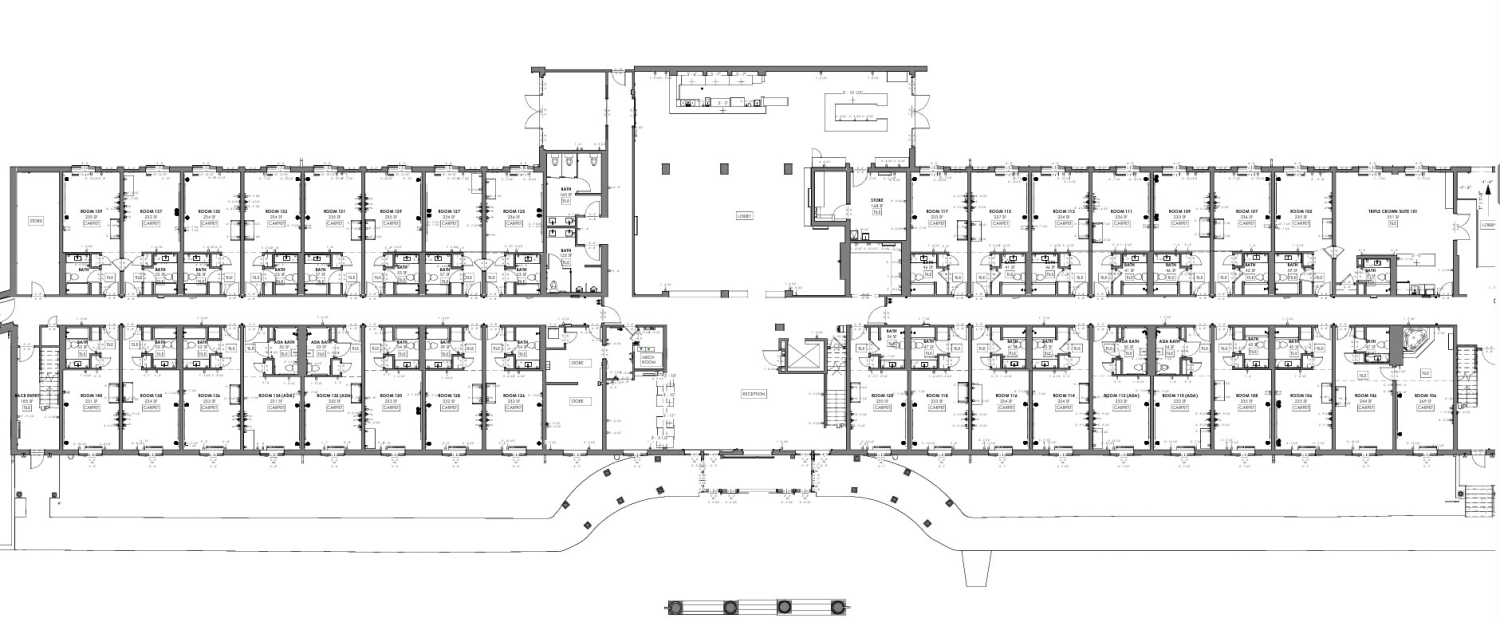

We recently completed one of our most comprehensive hospitality captures to date: a full hotel reality capture and scan-to-BIM delivery for the Clarion Hotel—Scan to BIM Services in Lexington. The assignment sounds simple on paper—document an existing hotel and build an accurate model—but the scope is anything but small. We document all existing conditions across 265 guest rooms plus approximately 45,000 square feet of amenity and back-of-house spaces, then translate that data into a coordinated Revit model that owners, architects, and contractors can use immediately.

Project Story and Scope

We are proud to present this project because it blends scale, speed, and precision. The hotel stays open the entire time, guests are moving, staff is working, and we have a firm four-day on‑site window to capture everything. Our team approaches it like a relay: plan, scan, verify, and keep moving. We work floor by floor and room by room to keep operations undisturbed, and we standardize our capture pattern so the data stays consistent from the first room to the last.

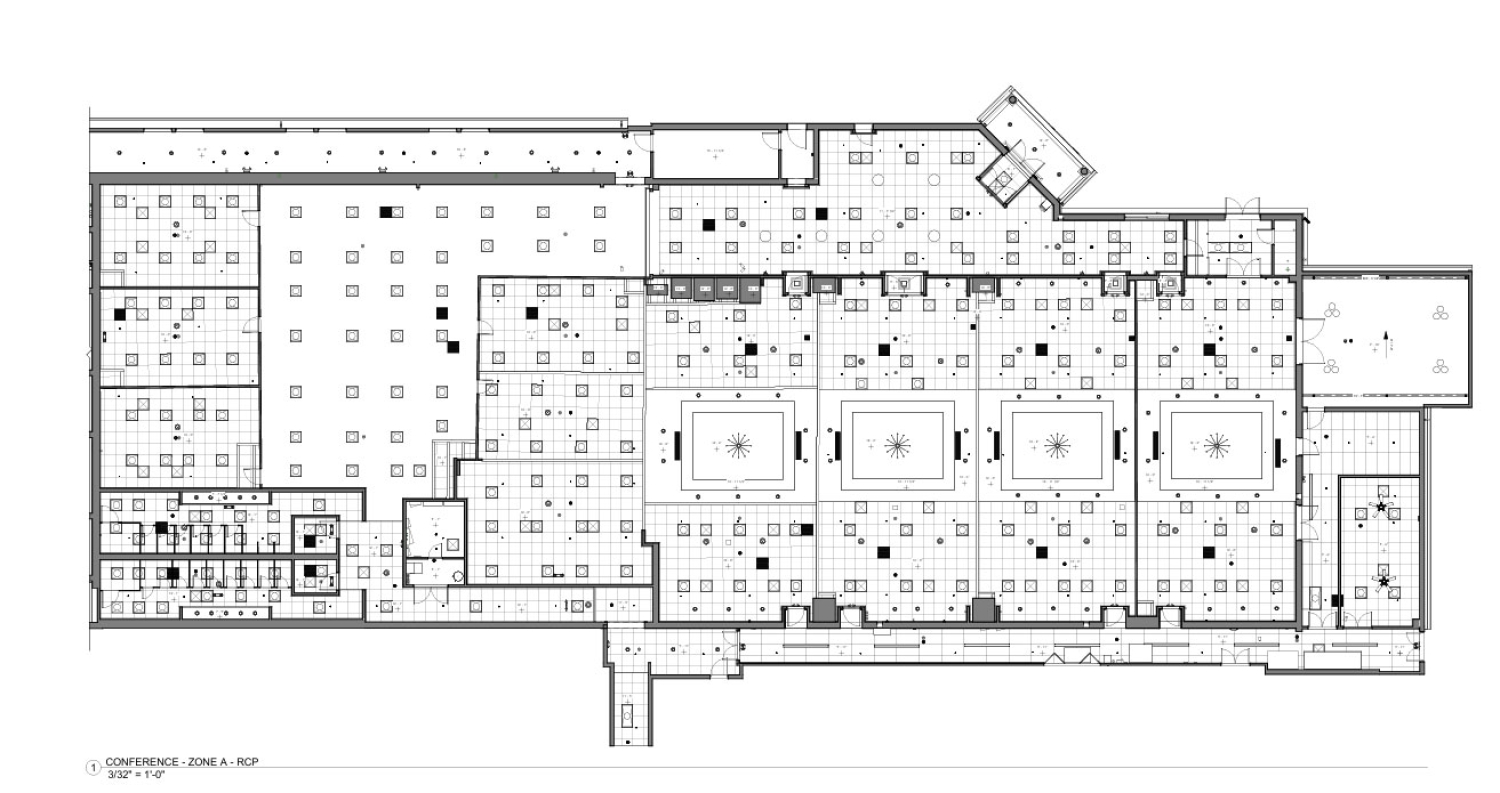

Inside the guest rooms we record room geometry, bathroom layouts, built‑ins and millwork, door and window types, and the visible portions of MEP systems—think supply and return locations, registers and diffusers, device plates, and plumbing fixtures—so the model supports both design and facilities needs. In amenities and back-of-house, we document lobbies, restaurants, meeting rooms, corridors, fitness areas, laundry and kitchen support, storage, maintenance shops, and service routes. Every area gets tied together in a registered point cloud that serves as the single source of truth.

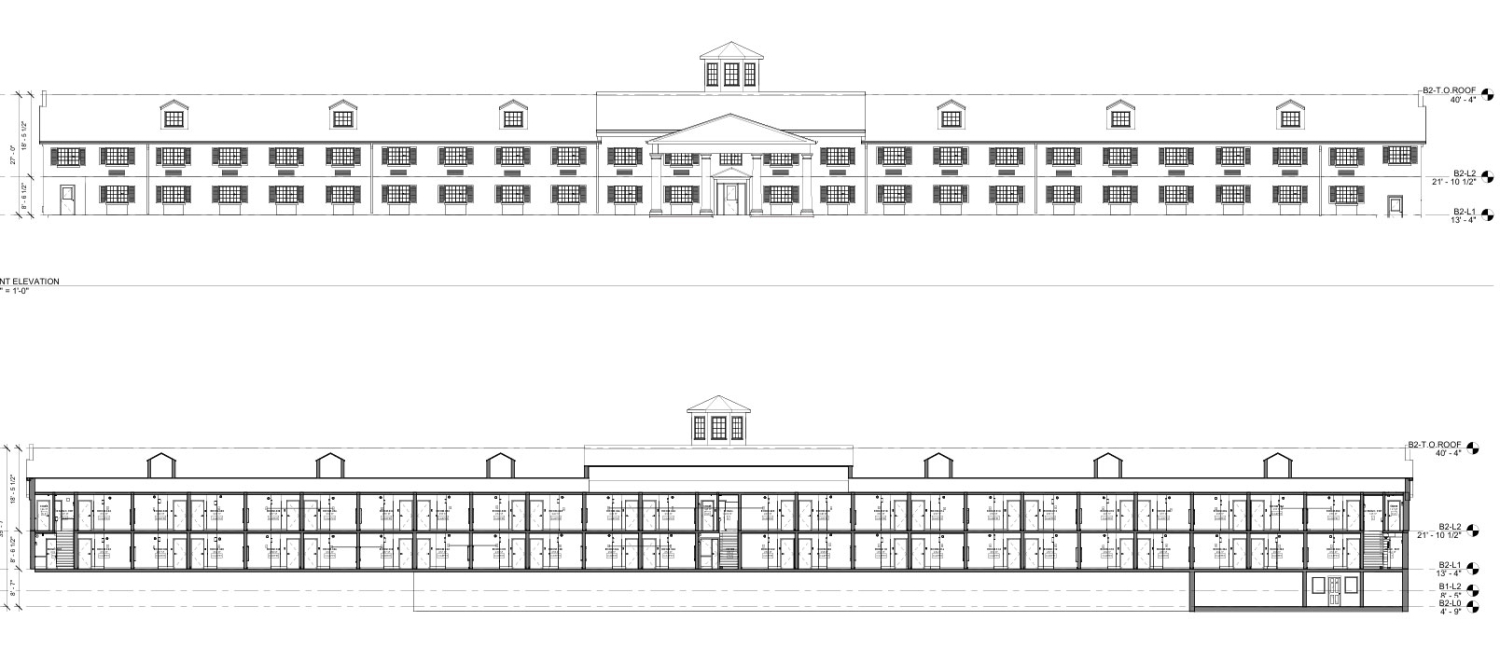

Our reality capture extends outside the building envelope, too. We scan exteriors, roof areas, parapets and equipment, site utilities, parking layouts, sidewalks, and terrain features. That exterior context proves invaluable when planning façade work, rooftop replacements, or site improvements—especially when schedule and access are tight.

How We Capture at Hotel Scale

We deploy mobile and tripod-based LiDAR scanning systems that collect millions of points per second and maintain tight alignment as we move through the property. Real-time registration and QA/QC checks keep the dataset disciplined so surprises don’t appear later in modeling. It’s a bit like speed chess: fast moves, but never at the expense of accuracy. And no, we don’t count outlets by hand—the lasers do the heavy lifting so we can focus on quality and coverage.

- Lead scanning technician managing equipment and on‑site quality

- Data specialist verifying registrations and organizing files in real time

- Project coordinator handling access, sequencing, and client communications

This cadence allows continuous capture with minimal interruption to hotel operations. When a space is occupied, we sequence around it and return later; when a window opens, we’re ready to move in. That flexibility is part of the value of a well-rehearsed field team.

Documenting MEP Systems with Practical Intent

Hotels live and die by comfort, uptime, and safety. Our documentation of mechanical, electrical, plumbing, and fire protection focuses on what design teams and facility managers actually need. We capture the routing and configuration of HVAC distribution, the layout of equipment rooms and air handling units, and rooftop placements that influence future replacements. We track electrical rooms and panelboards, major distribution paths, generator and emergency power interfaces, and room‑level device locations where they materially affect design. On the plumbing side, we capture domestic supply and waste stacks, hot-water distribution, and fixture groups. For life safety, we document sprinkler coverage patterns, mains, and standpipe locations, providing a reliable reference for compliance and renovations.

By keeping our field capture disciplined and our notes practical, we make sure the model reads clearly for both engineers and non‑technical stakeholders. If a designer needs to route new ducts through a corridor ceiling or coordinate a riser change, the model supports that decision instead of creating new questions.

Turning the Point Cloud into a Working Model

Back at the office, our modeling team transforms the registered point cloud into a coordinated Revit model with the appropriate LOD for planning, design, and early preconstruction. We maintain wall, floor, and ceiling assemblies; doors, windows, and glazing systems; and built‑in elements that drive layout decisions. We include room data with consistent naming and numbering, and we model MEP systems to the level required for coordination and quantity checks. Site and exterior elements—terrain, hardscape, lighting, and roof equipment—are integrated so teams have a complete context.

The timeline is straightforward: four days on site, then 45 days to full model delivery. That schedule reflects our standard scan-to-BIM workflow and nationwide production capacity. Accuracy stays front and center; we validate model geometry against control, spot-check complex intersections, and keep a clean handoff so downstream teams aren’t wrestling with messy files.

Why This Matters for Owners, Designers, and Builders

When the existing conditions are modeled accurately, projects move with less friction. Owners gain reliable floor plans, verified room counts and areas, and a central model for capital planning. Facility teams inherit clear, current documentation that supports preventive maintenance and troubleshooting. Architects and engineers reduce assumptions in early design, tighten coordination, and limit rework. Builders price more confidently, perform earlier clash detection, and plan phasing with fewer surprises. In a hotel environment, that translates to better guest experience during work, fewer unplanned outages, and a safer jobsite.

We also see a long tail of benefits: emergency egress analysis based on real geometry, more accurate takeoffs for finishes and fixtures, and faster stakeholder alignment because everyone is reviewing the same information. The model becomes a durable asset, whether the next step is a targeted renovation or a multi‑phase repositioning.

A Note on Place: Lexington and the Region We Serve

Delivering this project—As‑Built Drawings and Scan to BIM in Lexington—underscores our commitment to responsive service across Kentucky and the surrounding region. Hotel portfolios in this market are modernizing, and teams want dependable partners who can move quickly without sacrificing accuracy. With Nashville-based expertise and nationwide reach, we bring the same disciplined process to properties up and down the I‑65 corridor and beyond—so whether it’s a selective guest room refresh or a full systems replacement, the existing conditions start out right.

We’re grateful to the Clarion Hotel stakeholders and trade partners who coordinated access, shared insights, and helped us keep a tight schedule. Collaboration on the ground is often the quiet hero of a clean dataset.

Ready to plan your next renovation with current, trustworthy documentation? Let’s talk about as‑built capture, LiDAR scanning, and a right‑sized Revit model that fits your scope. Contact our team at Scan Skunks to schedule a walkthrough, request sample deliverables, or kick off a proposal.