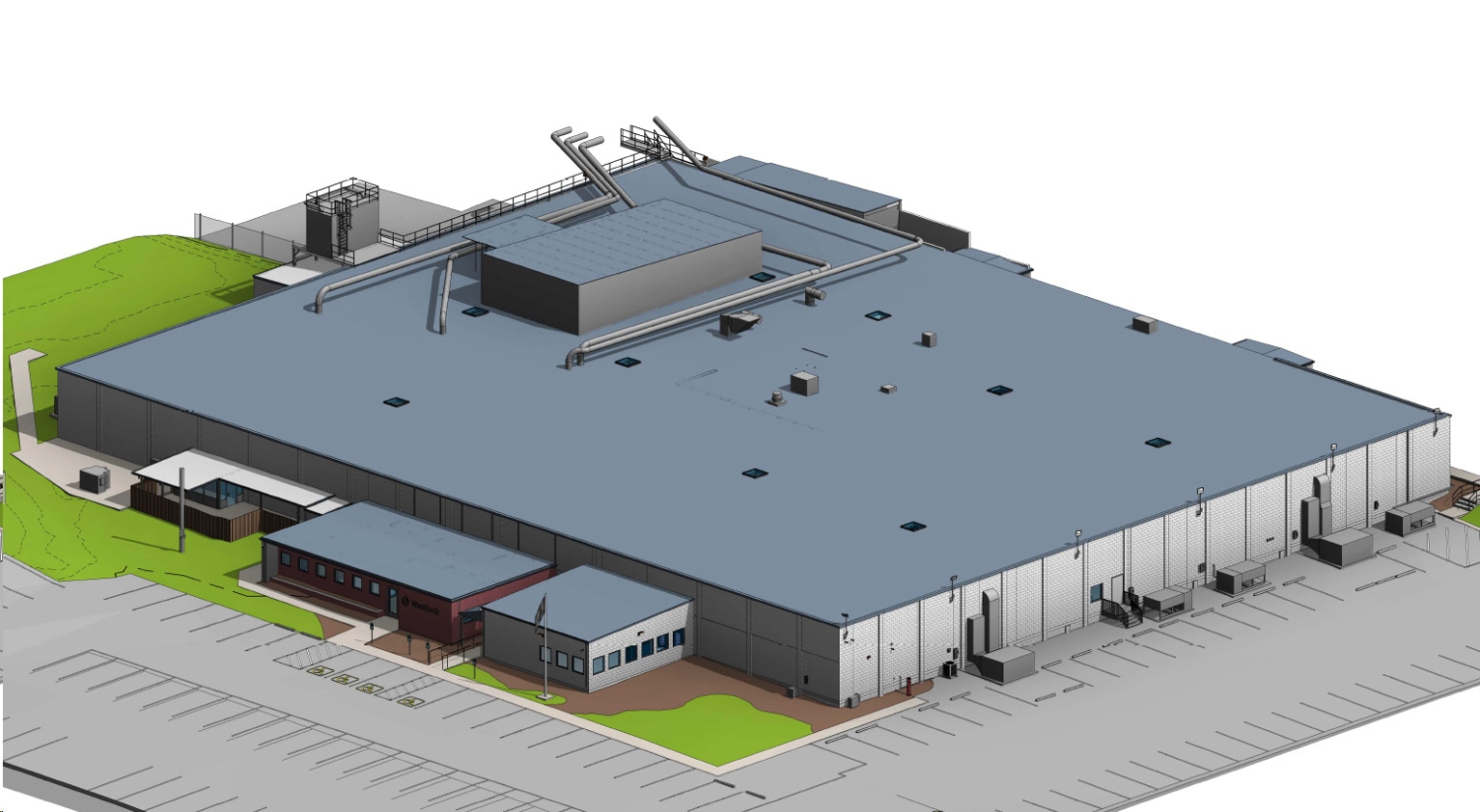

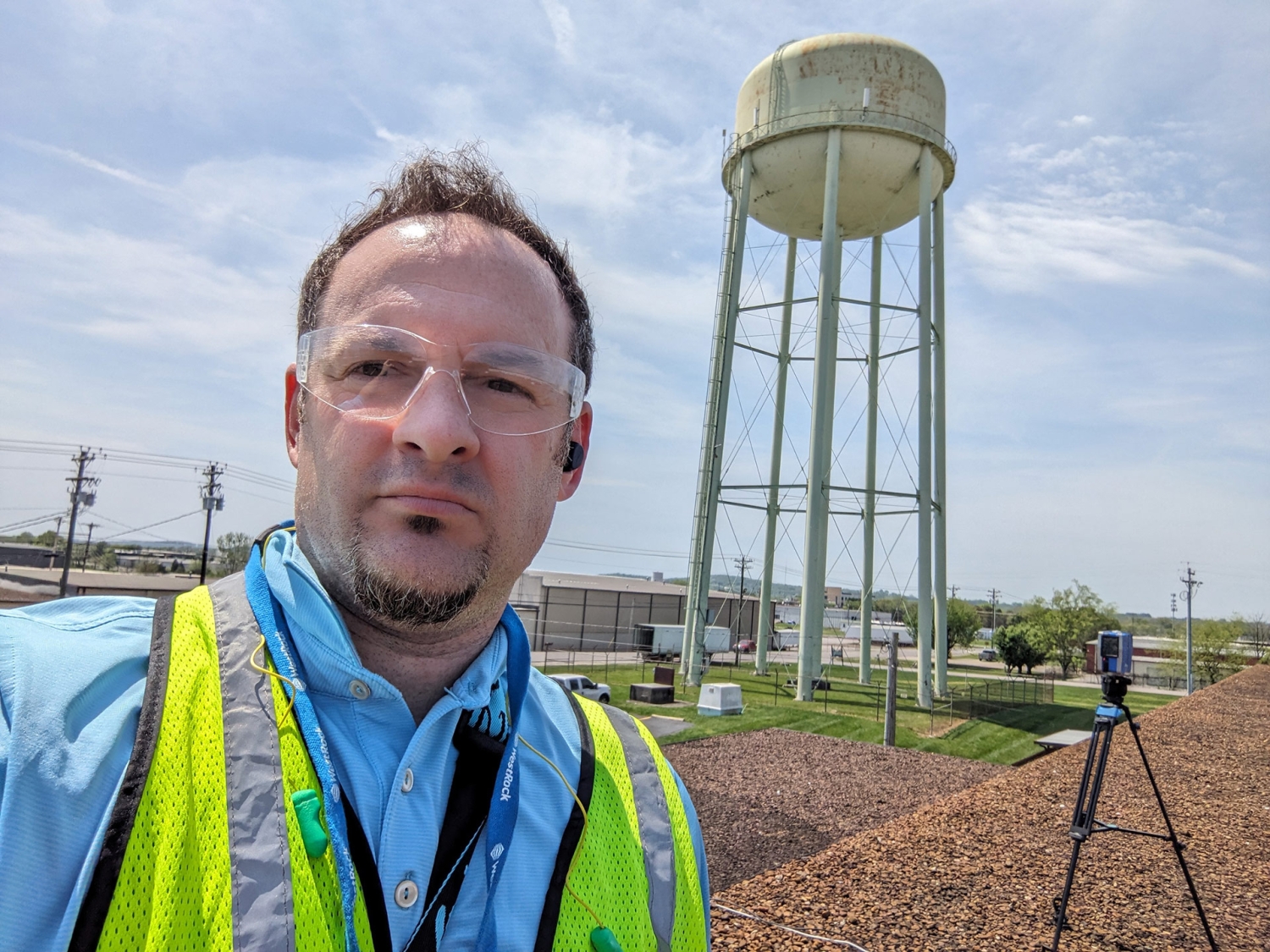

Industrial Plant LiDAR Scan and As-Built Drawings of a 65,000sqft Facility in Lebanon, TN

Project Description

In large-scale construction and renovation projects, the accuracy and detail provided by advanced technologies can make all the difference in ensuring a successful outcome. Recently, Scan Skunks undertook a project that involved LiDAR scanning and the creation of as-built CAD drawings and a Revit model for a sprawling 65,000-square-foot facility. A key focus of this project was the accurate documentation of the mechanical systems within the space—an essential element for the architects, engineers, and contractors involved.

The Project: A Complex, 65,000-Square-Foot Facility

The Lebanon, TN facility in question was a large, multi-use space with intricate mechanical systems, including HVAC, plumbing, and electrical components. Given the complexity and size of the facility, traditional methods of documentation and measurement would have been time-consuming and prone to errors. Recognizing the need for precision and efficiency, the project team chose Scan Skunks to provide state-of-the-art LiDAR scanning services, which would serve as the foundation for creating highly accurate as-built CAD drawings and a Revit model.

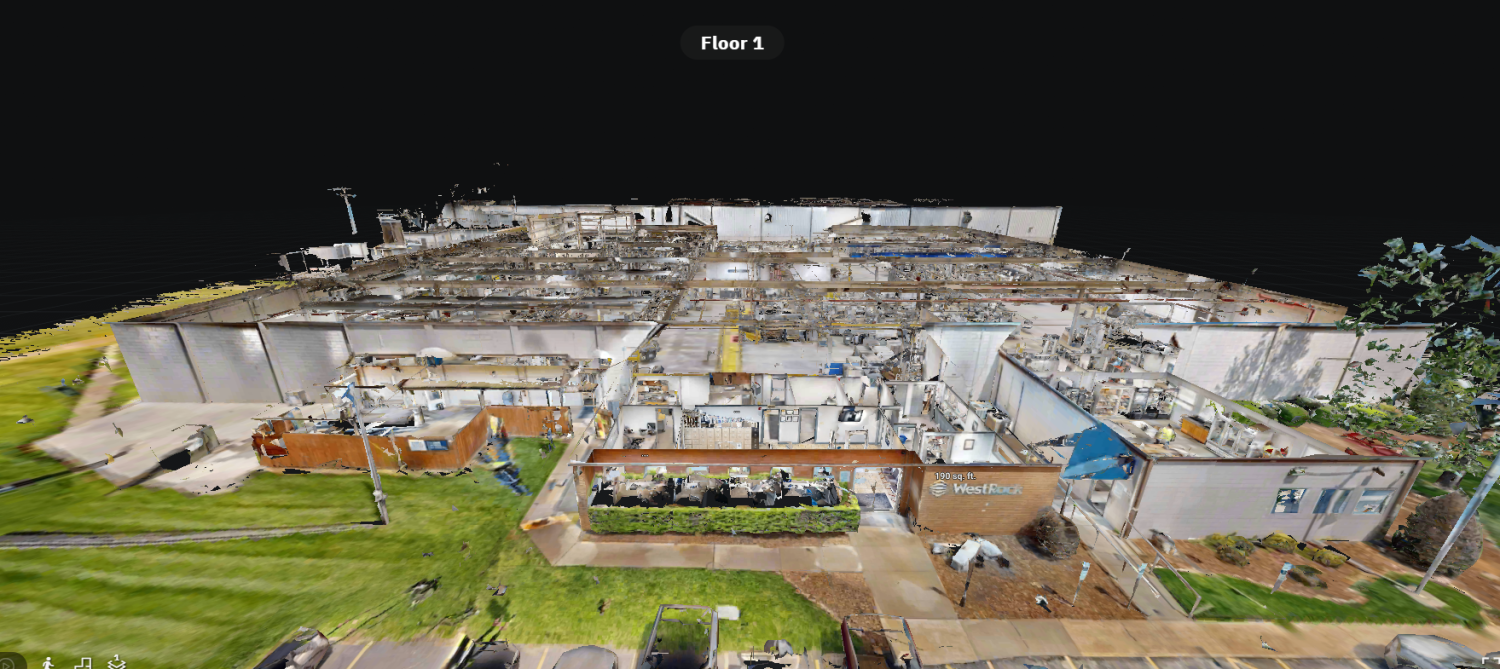

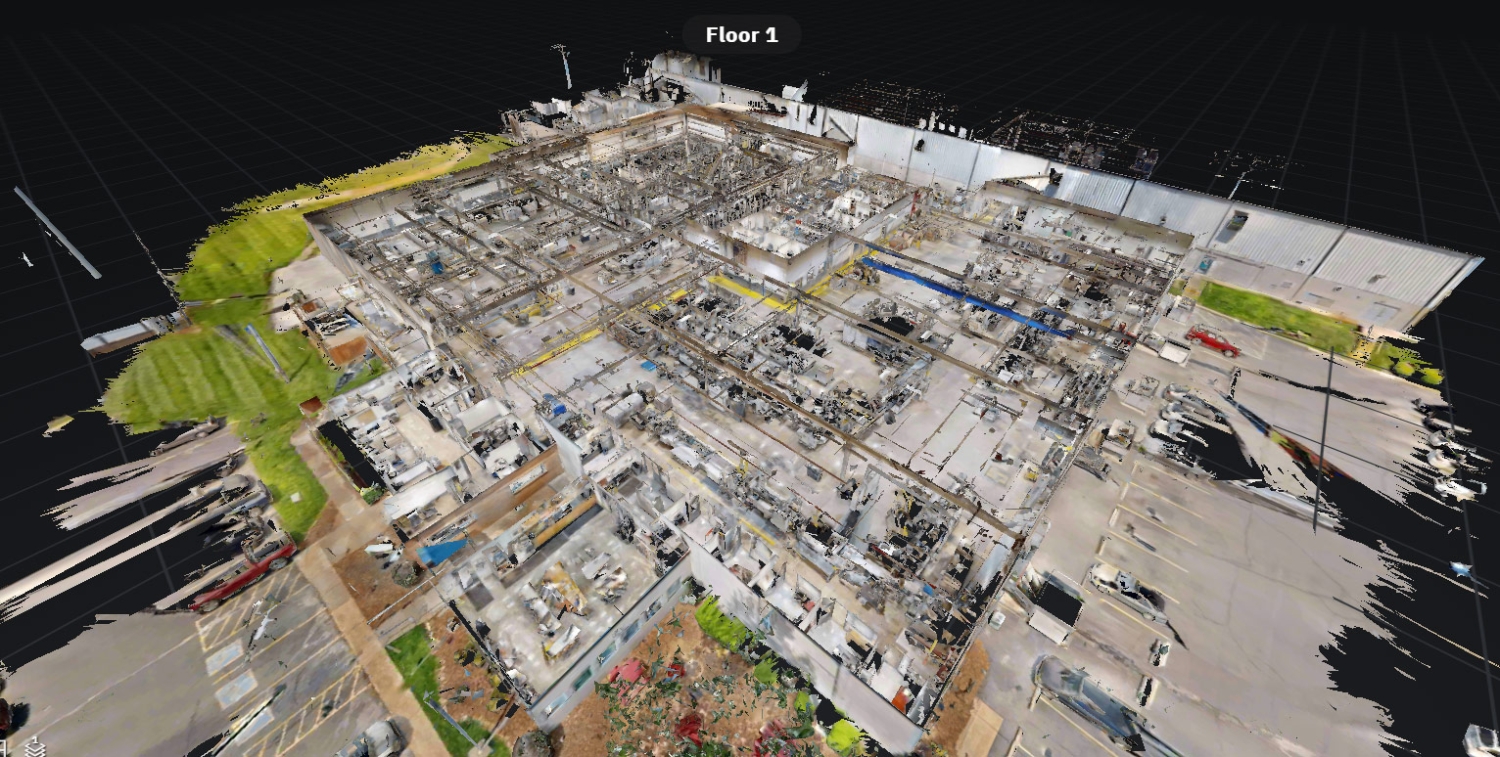

LiDAR Scanning Lebanon, TN: Capturing Every Detail

LiDAR (Light Detection and Ranging) scanning is a laser-based technology that captures the physical environment in 3D with remarkable precision. For this project, Scan Skunks used LiDAR for the Lebanon industrial plant to capture every square inch of the facility. The result was a point cloud—a dense collection of data points that represents the exact dimensions and features of the facility.

- Comprehensive Data Capture: The LiDAR scanning process covered the entire facility, including all visible structural elements, surfaces, and, importantly, the mechanical systems. Every duct, pipe, and conduit was captured in detail, ensuring that nothing was overlooked.

- High Accuracy: LiDAR scanning’s ability to capture data with millimeter precision means that the resulting models are far more accurate than those produced by traditional measurement methods. This accuracy is crucial when dealing with complex mechanical systems, where even a small error can lead to significant issues down the line.

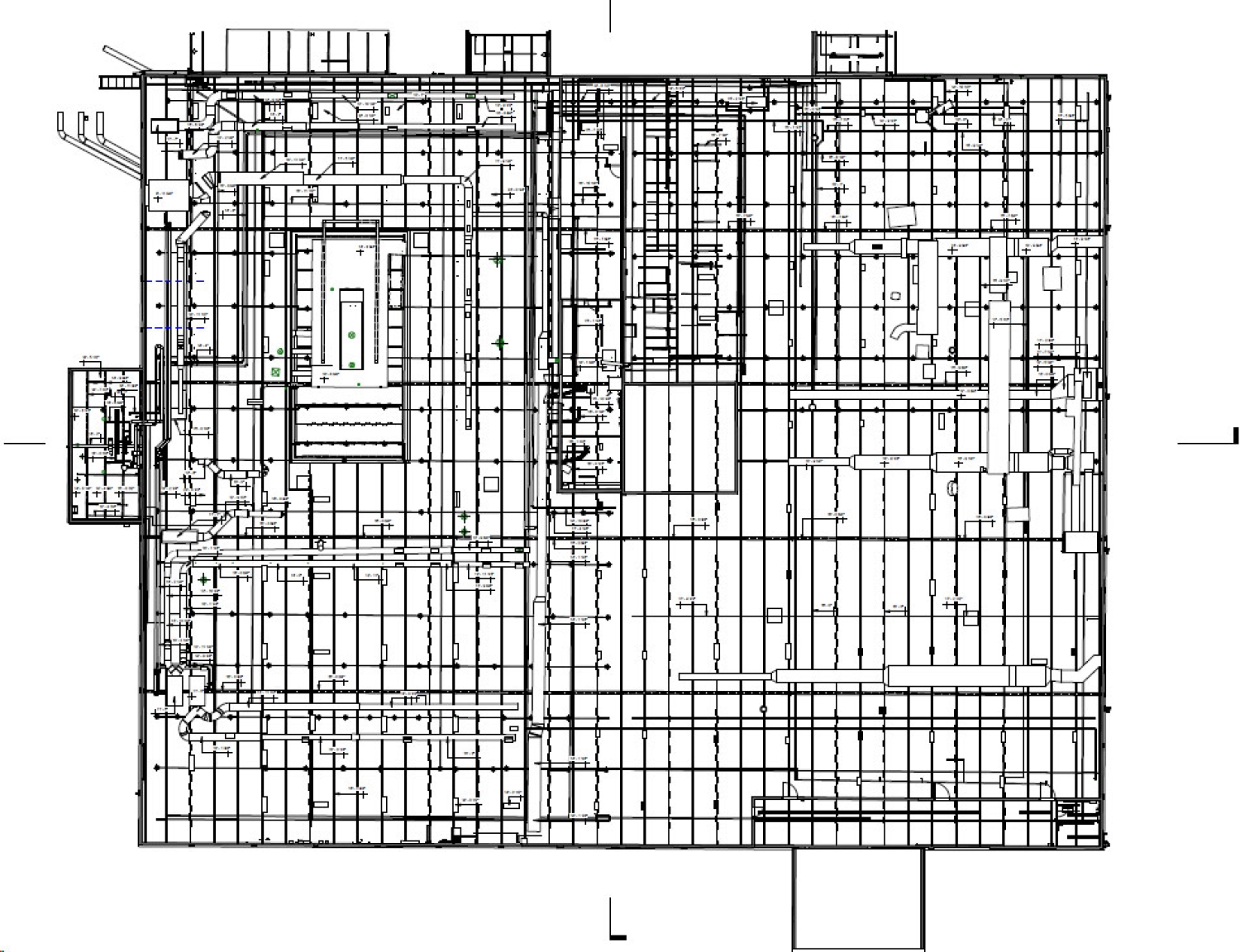

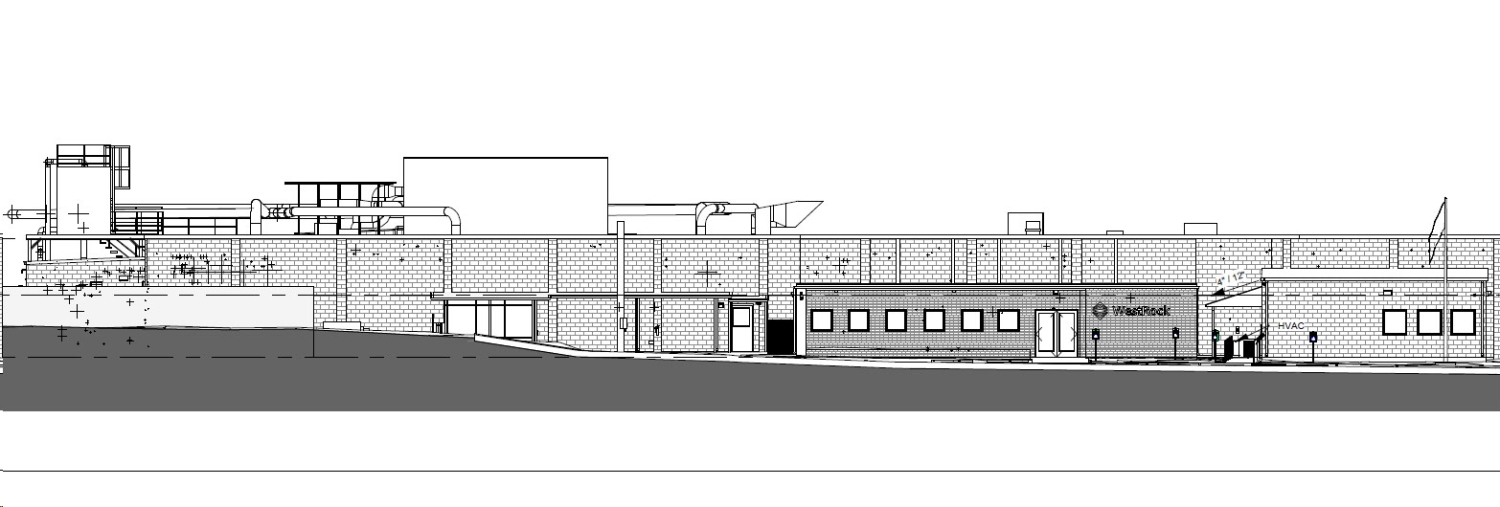

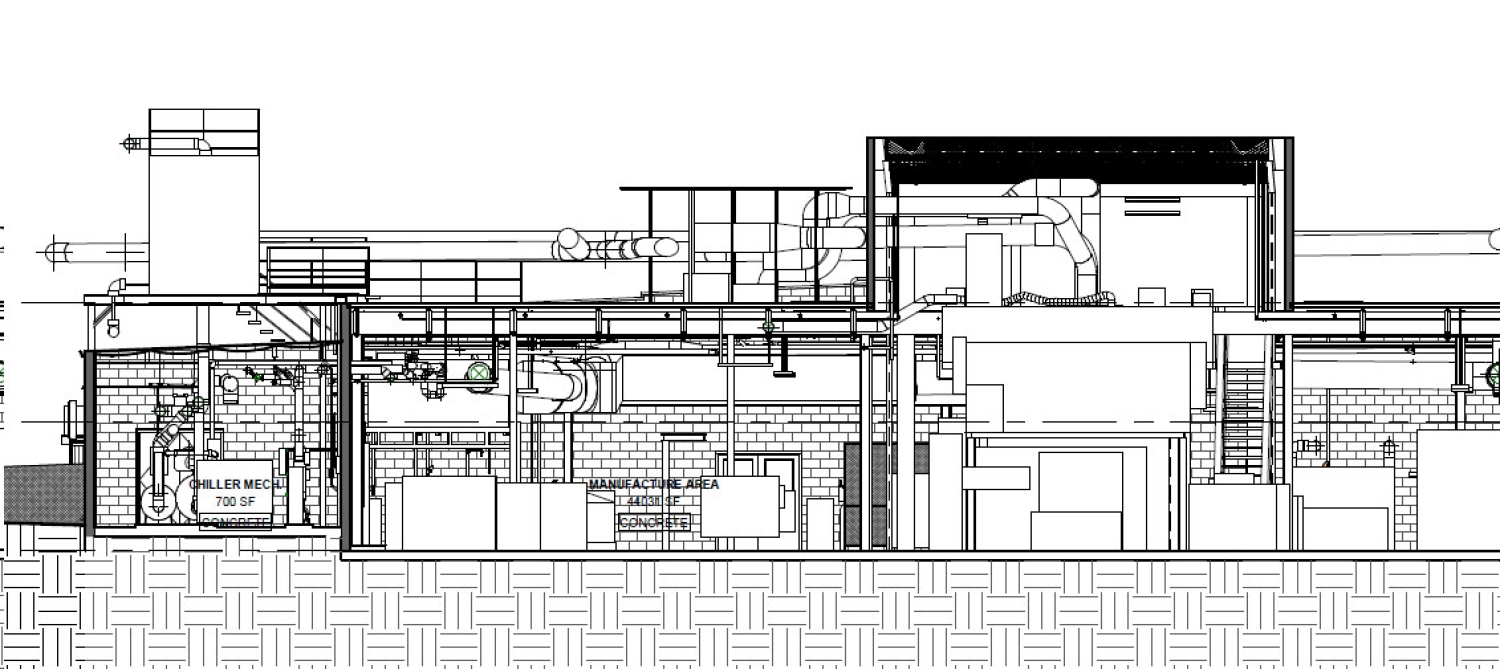

As-Built CAD Drawings: The Foundation for Planning and Design

After the LiDAR data was collected, it was processed to create as-built CAD drawings of the facility. These drawings serve as the foundation for planning and design, providing architects, engineers, and contractors with a clear and accurate representation of the existing conditions.

- Mechanical Systems Documentation: The as-built CAD drawings meticulously documented the mechanical systems within the facility. This includes the layout of HVAC ducts, the routing of plumbing pipes, and the configuration of electrical conduits. Having this information in a clear and precise format allows engineers to make informed decisions when planning upgrades, repairs, or new installations.

- Ease of Access: The CAD drawings provide a user-friendly format that can be easily referenced by all stakeholders involved in the project. Whether it’s for planning a new design, troubleshooting an existing issue, or coordinating between different teams, these drawings are an indispensable tool.

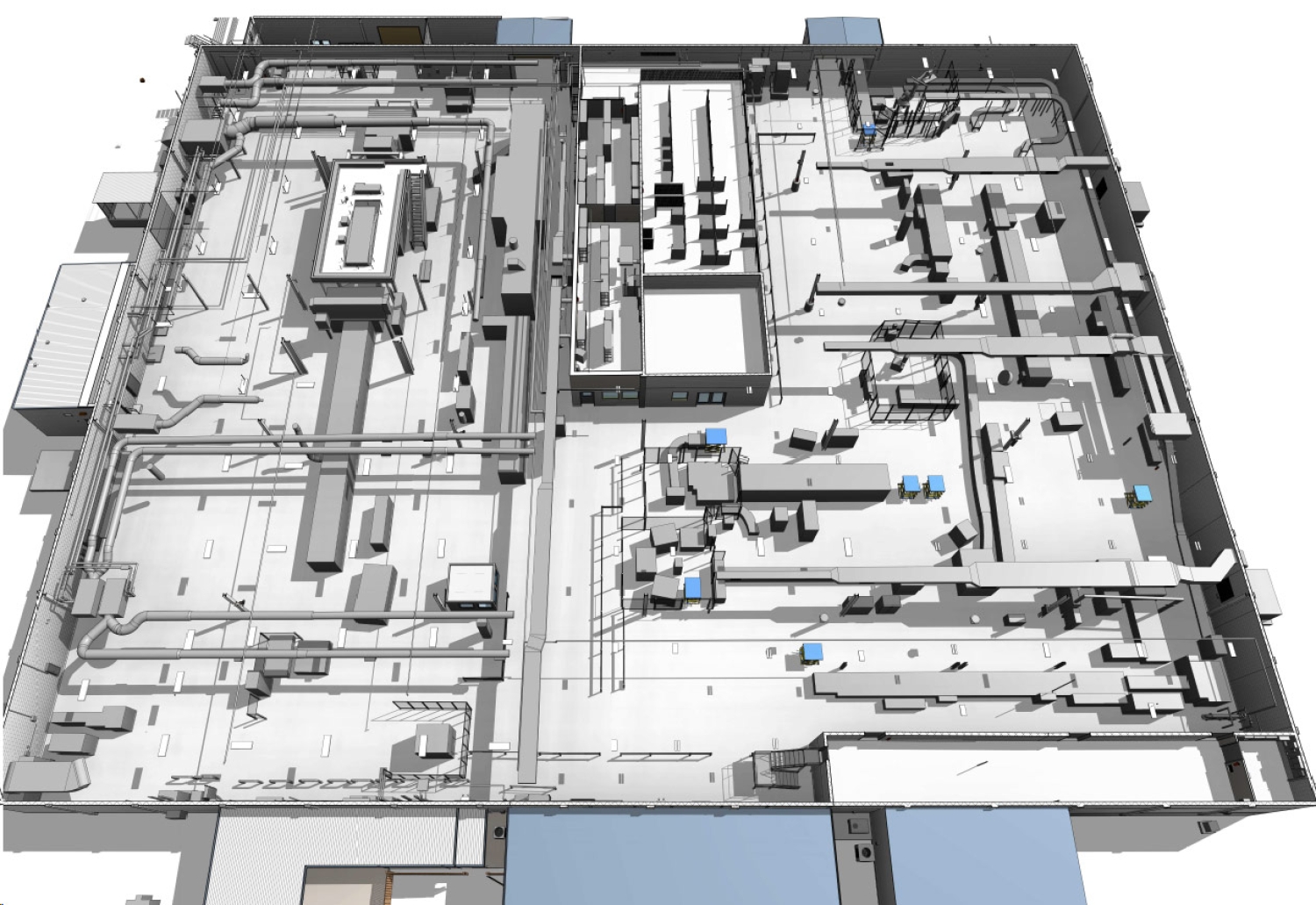

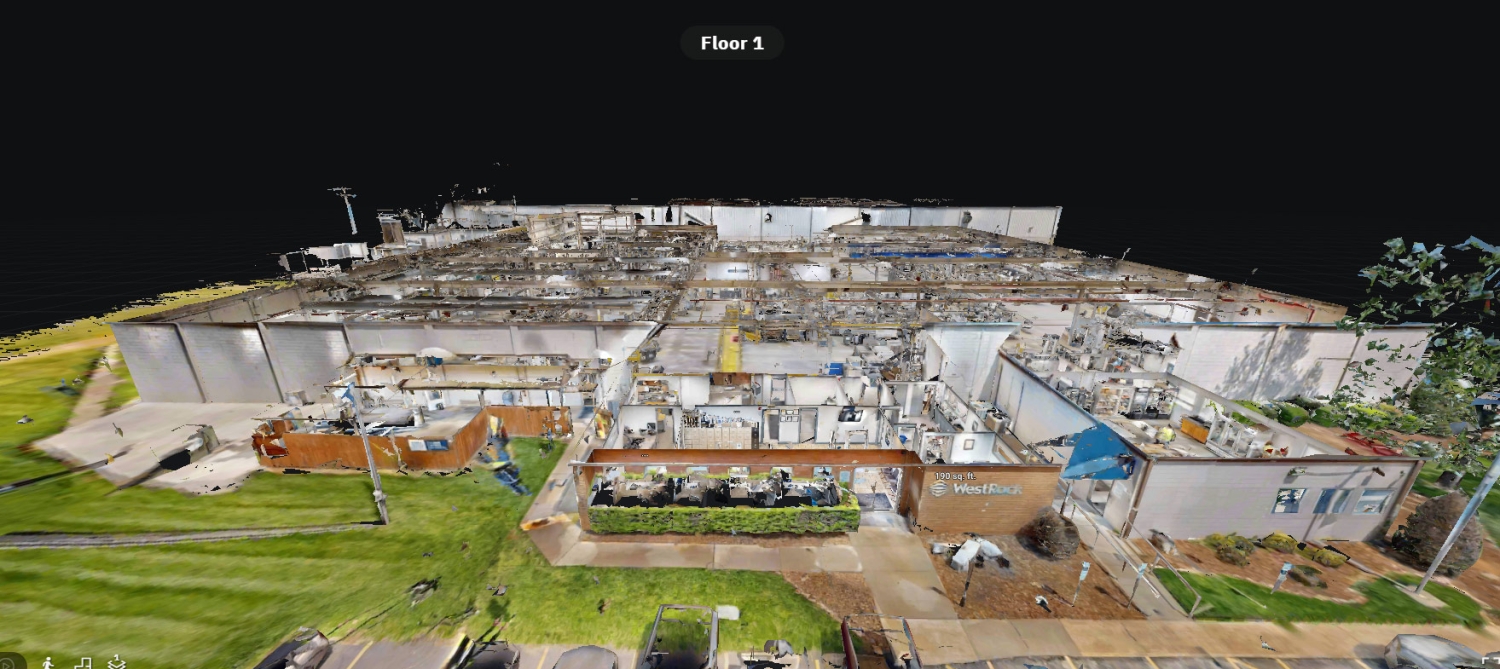

Revit Modeling: Bringing the Project to Life

The next step in the project was the creation of a 3D Revit model based on the LiDAR scan data. Revit is a powerful tool that allows for the visualization and manipulation of a building’s structure in a virtual environment.

- 3D Visualization of Mechanical Systems: The Revit model brought the mechanical systems to life, allowing the project team to visualize the entire system in three dimensions. This is particularly beneficial for engineers who need to see how different systems interact with each other within the space.

- Coordination and Collaboration: With the Revit model, all stakeholders can collaborate more effectively. Architects can ensure that new designs integrate seamlessly with existing mechanical systems, contractors can plan their work with precision, and engineers can simulate system performance before any physical work begins.

- Efficiency in Modifications: Should there be a need for modifications or redesigns, the Revit model provides a dynamic platform where changes can be made and visualized in real-time. This flexibility is invaluable in large-scale projects where multiple revisions are often necessary.

The Outcome: Precision, Efficiency, and Collaboration

Thanks to the advanced LiDAR scanning and the resulting as-built CAD drawings and Revit model, the project team was able to approach the renovation of the 65,000-square-foot facility with confidence. The detailed documentation of the mechanical systems ensured that all upgrades and modifications were planned and executed with the highest level of accuracy.

- Reduced Errors: The precision of the LiDAR scan and the accuracy of the resulting models significantly reduced the risk of errors during construction, leading to fewer delays and cost overruns.

- Improved Communication: With detailed CAD drawings and a 3D Revit model, communication among architects, engineers, and contractors was greatly enhanced, leading to a more streamlined and efficient project workflow.

- Enhanced Decision-Making: The ability to visualize the entire facility and its mechanical systems in 3D allowed for better decision-making, ensuring that the final outcome met all design and functionality goals.

Conclusion: The Future of Construction and Renovation

This project demonstrates how LiDAR scanning, coupled with as-built CAD drawings and Revit modeling, can transform the way large-scale construction and renovation projects are approached. By providing a precise and detailed representation of the existing conditions, Scan Skunks enables architects, engineers, and contractors to work more efficiently, collaboratively, and confidently.

If you’re involved in a complex project and need the accuracy and detail that only LiDAR scanning can provide, Scan Skunks can benefit your next project.